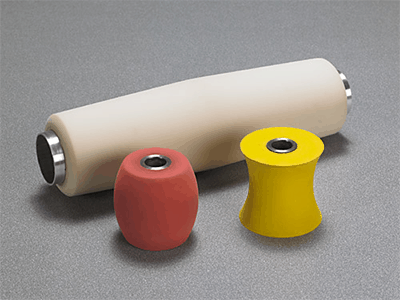

Critical Crowns, Contours, and Coverings

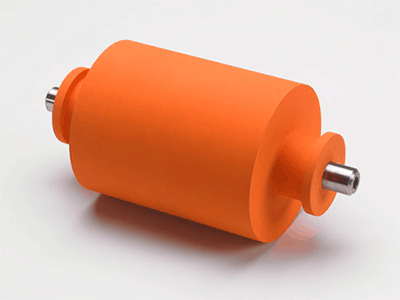

Harwood Rubber Products has a number of highly precision lathes capable of providing extremely close size tolerance and specific diameter requirements, suitable for your demanding rubber roller applications. Our equipment is set up and maintained to give your order repeatability over the entire lot of your critical parts.

Greater precision for closer tolerances

We offer extremely precise straight and parabolic crowns, concave and convex contours, trapezoidal and custom contours with tolerances as small as .002” from end to end and throughout the crown. We can accomplish this on a large variety of our different formulations and durometers (hardness) and be very specific to your rubber coated roller application.

With closer tolerances realized, our customers can see improved efficiencies through increasing speeds, and corrected tracking problems. Our customers see reduced product defects and machine down time. Our goal is for you to realize a better final product.

Minimal or no adjustments necessary

Our CNC equipment can be programmed to set a profile to fit your exact requirements, allowing minimal adjustment once your rubber roller(s) is put back into service. Our customers have found our quality has actually eliminated the need to “tweak the machine” after installation.

Harwood Rubber Products has provided customers with finished rubber coated rollers that maintain a close gap tolerance throughout a wide arc nip, with a gap held to within .010” over as much as a 10 foot span. We have provided many perplexed customers with solutions to their obsolete and/or antiquated/retro-fitted equipment. Harwood Rubber has been able to get their machine back up and running as designed.

Feel free to give us a call and see how we can help you to improve your machine’s operation. Call us at 330-923-3256 or email us at info@harwoodrubber.com.