Rubber Roller Manufacturing and Repair Services

Harwood Rubber Products, Inc. can provide all your custom rubber coated roller needs. Whether replacing, repairing, reconditioning, recovering, resurfacing, regrinding, recoating, or fabricating new rubber rollers, Harwood Rubber specializes in delivering cost-effective solutions. We work with your AutoCAD and traditional drawings, but are capable of advanced reverse engineering your existing worn rubber rollers. Rollers may be up to 20’ in length, 48″ in diameter, and weighing up to 3 tons per roll. We welcome small orders including prototype production, and maintain short lead times.

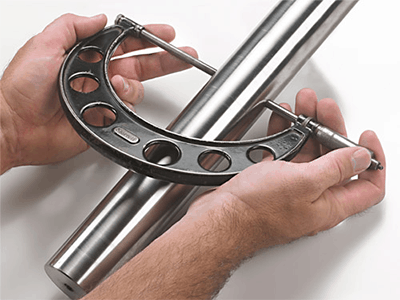

Harwood has a large inventory of roll covering compounds available to quickly respond to your emergencies. We can formulate the covering to your specific service condition and provide you with the most suitable material with the most effective durometer (rubber hardness) ranging from 5 to 100 Shore A. We hold tolerances as close as ±0.001″. Harwood can provide a wide range of grooves, finishes, crowns and tapers. We’ll maintain your exact specifications over your entire order and consistently from order-to-order.

Services include

- Molded parts

- Prototype work

- Regrinding and repairing rubber rollers

- Rubber rings/tubes

- Rubber to metal fabrication

- Specialty pulling lagging

- Repairing worn or damaged bearing surfaces

- Specialty pulling lagging

- Rubber roller resurfacing and recovering

- Rubber rollers reconditioning and replacement

- Recoat rubber rollers

Harwood has worked with a variety of core types including steel, aluminum, titanium, magnesium, brass, and metal alloys, along with a number of non-metallic substrates, such as micarta and linen.

Same day service is available for regrinding rubber rollers. Breakdowns take priority. Pick-up and delivery service is available.

Contact us today to learn how your project can benefit from our rubber coated roller fabrication and repair services.